Welding Basics

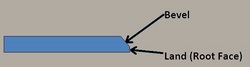

The first thing that will be discussed it the different Joints then the different positions. There are 5 basic types of Joints there is the Butt Joint, Corner Joint, T-Joint, Lap Joint, and the Edge Joint. Some of the Joints might include a Bevel with or without a Land (Root Face). Another thing that must be defined to describe any joint would be the type of welding position. The different welding positions are: Flat, Horizontal, Vertical and Overhead. Each will also indicate whether it is a groove, fillet, etc.

When you get ready to weld on a part it is important to make sure the weld size is correct. This can be done by many different methods, I would recommend getting the book Design of Weldments by Omer W. Blodgett. This book is a great resource and can help you in determining the weld sizes that you will need. Also check with any code that you are designing to they may have a pre-determined weld size that you have to use.

The Butt Joint

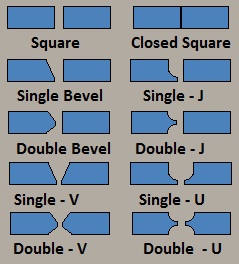

Butt Joint Configurations

The Butt Joint is a common joint that is usually seen with a Bevel and a Land. The Joint can have the pieces placed flush against each other, but more commonly has a root opening. There are many different types of Butt Joints which are: Square, Single Bevel, Double Bevel, Single-V, Double Bevel, Closed Square, Single-J, Double-J, Single-U, and the Double-U.

The Joint is welded in all the different positions and is almost always labeled as a groove weld. It is commonly used in the pipe and sheet metal industries.

The Joint is welded in all the different positions and is almost always labeled as a groove weld. It is commonly used in the pipe and sheet metal industries.

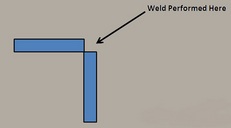

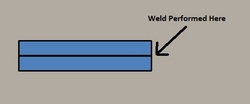

The Corner Joint

The Corner Joint is where the two pieces form a V or L-shape. The weld will be performed on the outside edge of the piece. This is used often in the sheet metal industry. The T-Joint is also welded in all the different positions.

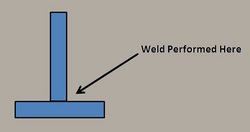

The T-Joint

The T-Joint is where the 2 pieces come together to form a T-shape. This joint is a very common joint and is considered to be a fillet type joint. The weld is performed on the inside of the T-joint. It sometimes will have a Beveled edge. This joint can have a single Fillet, Double Fillet and a Single Bevel.

The Lap Joint

The Lap Joint is when you have to members actually lapping over each other. This type of joint can have a Slot or Plug Weld, Fillet Weld or a Resistance Weld performed. This type of joint is used regularly in the sheet metal industry.

The Edge Joint

The Edge Joint is where to members are placed side by side and welded on the edge.